FAQ

You can find answers to common questions here.

What if you can’t find what you are looking for? Then, please send a mail to salesdepartment@proces-data.com

Components

(for example to create a program for a system with 5 pump-stations and 2 central pumps, but then use the same for a program with only 3 pump-stations and 1 main pump without creating a new main assembly?)

One assembly with the max-system, is not the way we suggest, and not the way VIGO6 is intended. It’s better with small building-block, which are put together to match the single system.

Let’s say you have 2 different systems; the two variants you have described.

Create a main-assembly with 3 pump-stations and one main pump. Create the necessary visualizations for it. Add this visualization to the display(s) in the main-assembly.

If it is possible ‘just’ to add 2 extra pump-stations and 1 main pump, without any other changes, an idea is just to make a decedent of the first main-assembly and in here just add the extra 2 pump-stations and 1 main-pump. In case it visualization is made in a way, so these new thing is just extra pages on a swipe-view, you can just create a dependent of the first visualization and add the extra pages.

This approach though requires that view is not added to the Display before you make another descendent of each main-assembly and use these in the projects.

Editor

Pressing F1, shows a help page, where a list of short-cuts is shown. This help page also contain programming examples / explanations.

Hardware modules

Indeed you can. Use the PD690 Automotive Power Protection with the base module BM108. You can connect it to its base module BM018.

You can use it with other modules than VIGO6, even with non-PD hardware.

For purchase information contact salesdepartment@proces-data.com.

Yes indeed.

You have three options:

Choose the PD803 COPP DPI which also includes a GSM-modem supporting 2G/3G and GPRS.

Choose the PD804 COPP DPI which also includes a GSM-modem supporting 4G LTE and GPRS.

Choose the PD947 GPS Navigation Receiver.

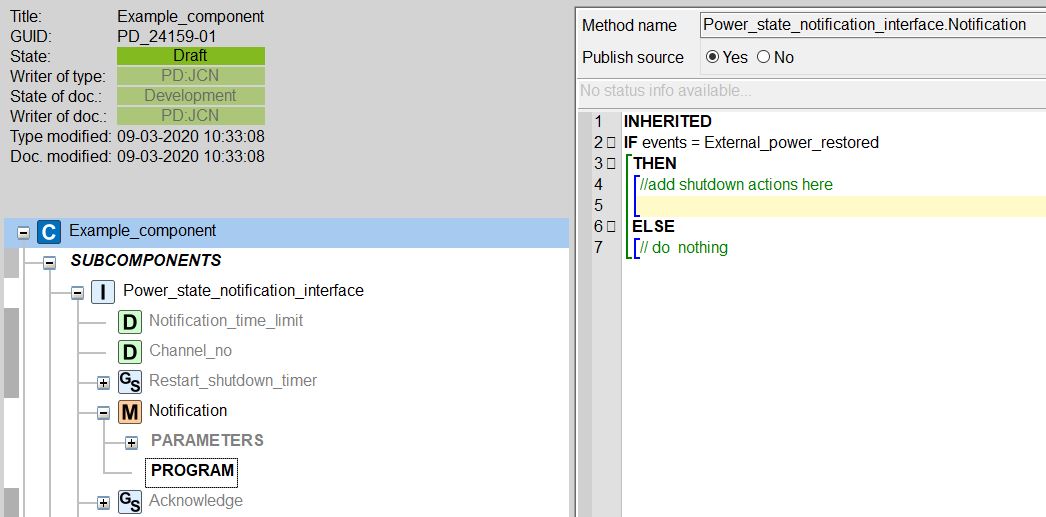

The hardware-interface PD_16494-06 – Power_state_notification_interface is a subcomponent. You can add it to all the components where you want to handle changes in the power state.

When the power state changes, you get a notification. Further, you get the current power state in the local variable “events”. One of these states is “External_power_lost”. In other words, you get this event, when you lose the main supply, and your device runs on a battery.

See the small basic example below.

Nb. Once you add the interface you can only locate your component in devices with batteries (i.e. PD 688, PD 803, and PD 802).

Reset button and diode

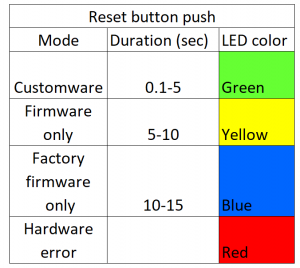

You use the reset button to reset a module or change its mode. The module’s diode will show its mode. When you press the button, the diode will turn off for 100 ms as a response. You can make the diode blink through a method call.

Customware

After a normal reset, the module will run the firmware and customware that you have downloaded to it, and the diode will show a green color.

Events that trigger a normal reset:

– A power failure.

– A P-NET call to a “reset”-method.

– A press under five seconds on the reset button.

Firmware only mode

If a customware program on a module causes an error, you can start the module in “firmware only” mode. The module will never call the guest component, only the firmware. Now, you can download new customware and activate that instead.

You change to “firmware only” mode with a press on the reset button for five to ten seconds. The color of the diode will be yellow.

Factory only mode

This mode is for when you have a major problem where you can’t even connect to the module in “firmware only” mode. In that case, you force the module to run its factory firmware. As a result, the module will lose its non-volatile data, including the P-NET settings. The factory firmware is the firmware it had when the module left PROCES-DATA.

You change to “factory only” mode with a long press on the reset button for ten to fifteen seconds. The diode will be blue.

Dead or busy

The diode is a constant red, and you can’t change its mode. The module needs service.

Download

The active customware on your module runs, while you download to it. In effect, the downtime for the module is short.

Power-up while you press the reset button

It will activate “factory only” mode. You can use it to mount a module that you have already used for another purpose. You install the module in a plant with a power supply, while you press and hold the reset button down. Afterward, it will not interfere with the communication in your system, because you reset its P-NET settings.

The table has an oveview of the different presses and the colors.

You need a PD688 or a PD804 to be able to print from VIGO6.

The printer must:

• Support USB

• Support ESC/POS command format

Printers listed below are still working with our products, but may no longer be available from manufacturer.

Please check this link for printers available from the printer manufacturer on our website:

| EPSON TM-T88V-042 model M244A | CITIZEN model CT-P293 | EPSON TM-T70II – Model: 296A |

|

|

|

IT and Support

Your PD-contact person can help you sort out what kind of support you need, and what is appropriate for your specific problem.

If we need our VIGO6-experts to have a look at your problem, they will typically ask for a support file.

Instructions on how to generate a support file:

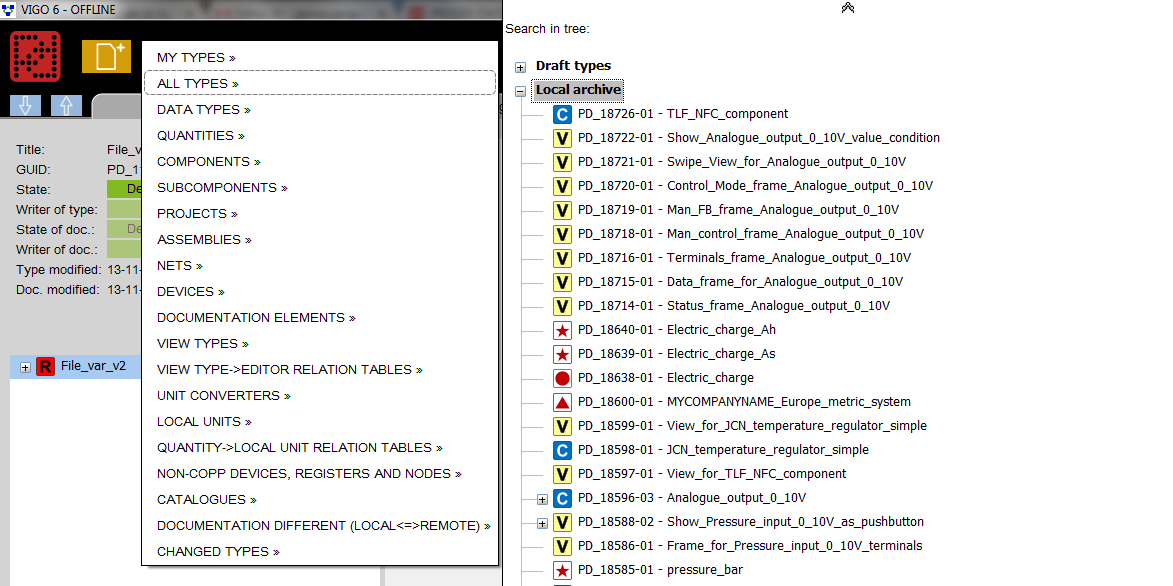

You can continue working offline on all the content in your local archive. Once you are back online, you can then push your work to the company’s archive (signer archive) for safekeeping. You can find the content of your local and company archive in the editor by selecting “open”-> “All types”.

In addition, the section “Draft types” contains a subset of the local archive. It holds all the types you are the writer of, and that you have not yet pushed to the company archive. It means that anything in the “Draft types”-section only exists on your local PC.

PROCES-DATA hosts your VIGO6 server. It communicates with TCP on port 35349. In short, change the company’s firewall settings to allow communication on that port, and you are ok.

We have seen significant speed improvements when using an SSD-disk between using a non-SSD-disk.

Therefore this is our most important recommendation for the workstation used to run the VIGO6-editor.

Programming

While PROCES-DATA has designed the modules for 4-20mA inputs and outputs, it is still possible to use a 0-10V input.

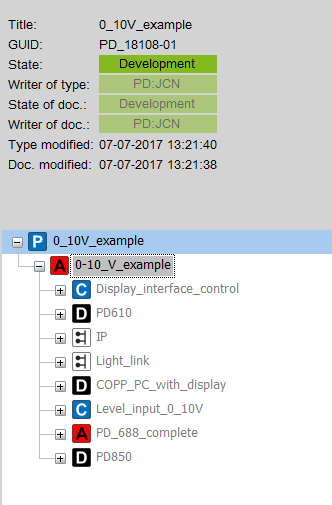

Below is an example of a 0-10V level input transforming the 0-10V input signal to a length.

We have implemented basic error handling, which means that it will signal to its supervisor if it has an error. You can operate it in “manual feedback”, “auto” and “disabled”. For more info on the built-in functionality of the process component see tutorial 7.

The component is PD-18096 and in the documentation section, you can see what it does. Basically, it reads a voltage and converts it to meters.

We have also created a view for the component (PD-18048) and for the assembly (PD-18117). But, you have the possibility to create your own too.

As we have mentioned in the documentation for the component, you can only locate it in a PD850. Additionally, you need to set operator rights in order to edit and see the view.

If you do not add any operator control, you will likely not see any fields on the views we have made. That is why we have added component PD-17553 Display interface control to the assembly. In effect, we can add the login or logout button to our assembly view. This enables us to play around with operator rights.

To see how you can use the component, there is a project with the GUID PD-18108.

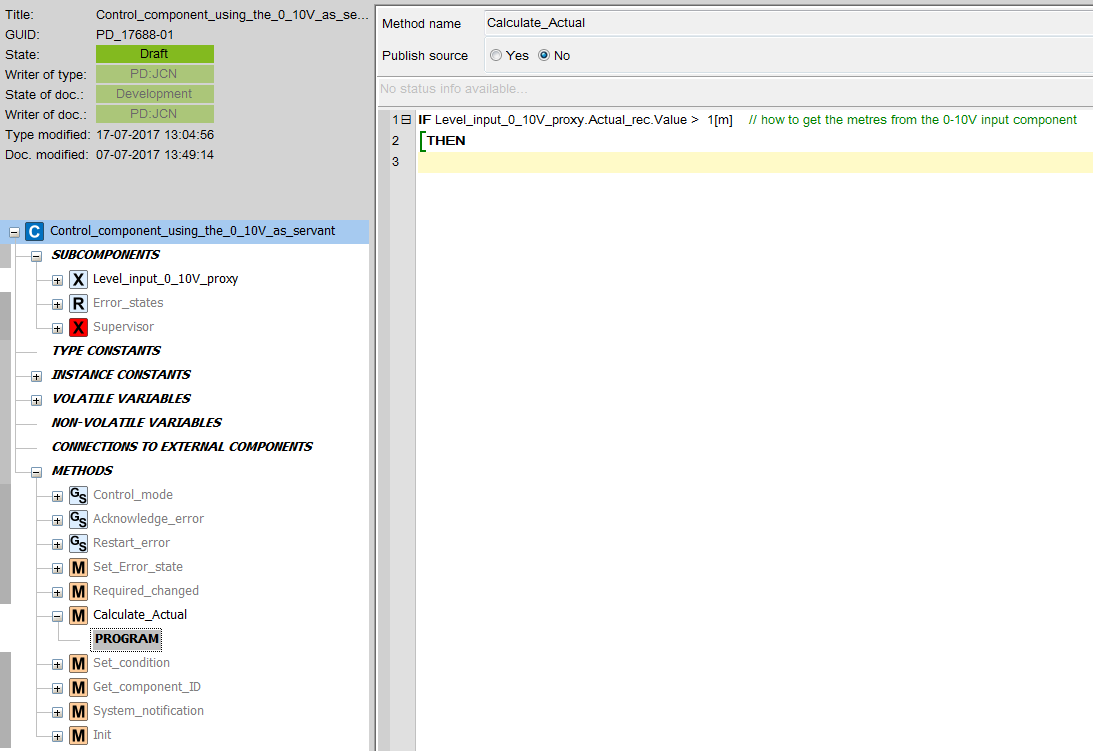

If you want to interface to this component in your overall control component, then do it as a “supervisor-servant”-connection. Below you see how to access the “level in meters”

In case you want to change data shown in the watch (it is also possible to alter local variables), the code must be in a stopped state (in a breakpoint for example). Then simply double-click the data you want to alter and type in the new value, and press ‘Enter’.

This can be very useful; to test another behavior of your program (could be changing a state-machine state variable).

Program download with PD 688

If you require new features or program changes in a project, and you want to use a PD 688 as a device for download, then you can do the following steps.

STEP 1:

Make the updates you want to your project.

STEP 2: Prepare the downloader PD 688

- Add a new device as PD 688 to your project assembly and give it a proper name.

- Connect the new PD 688 to your chosen network, for example, IP.

- Add a visualization for the Configurator (PD_3184-xx – View_for_Configurator) as a Guest view for the new PD 688.

- Insert the right serial number for the new PD 688 in your VIGO6 project.

- Build the project.

- Download the Customware to the PD 688 and see that the download screen shows on the PD 688.

- Copy the ‘Output’ folder from the project folder in your VIGO6 library to an SD card. You have to place the ‘Output’ folder in the root of the SD card with the name ‘Output’.

- Insert the SD card in the PD 688.

STEP 3: Use the PD 688 for download

- Connect the new PD 688 to the running system in the field via the desired network.

- Switch on power for the new PD 688.

- Press the button for ‘Config all modules’ and the PD688 will download new customware to all devices in the running system.

- Your running system now contains the new Customware.

First, locate your components into devices – which will give you the automatic configuration. The method is that the first output you add gets the first output channel. The first input you add gets the first input channel etc. The system only allocates to an I/O channel, when all I-channels are full.

You can change the allocation:

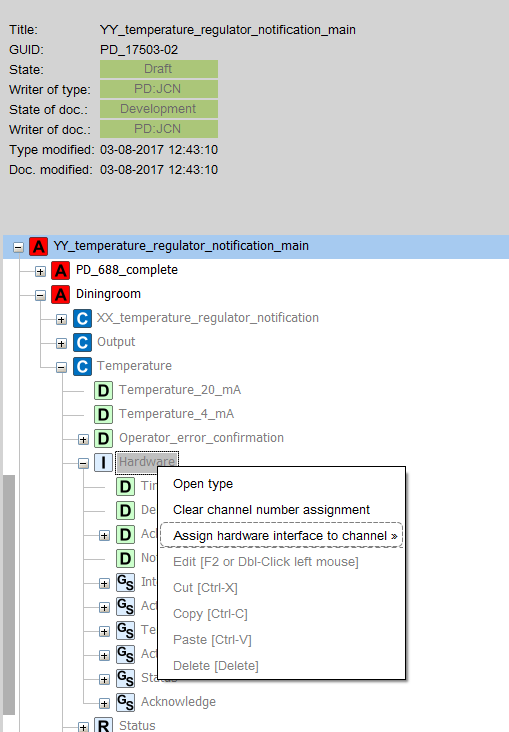

Find the Hardware interface of the component.

Right-click and then select “Assign hardware interface to channel”.

If you have “filled” all channels in the device, you can start by clearing the channel number on a few of the components, so you have space to move around.

How do I change units? I would like to have volume in litres and flowrate in either m3/h or L/min.

Using one of the predefined “Quantity local units relation table”

All units in VIGO6 are stored as SI-units but can be displayed as any derived unit you want.

Volume in Litres and flow rate in liters per second are already defined and are e.g. used in the “quantity local units relation table” PD_12849 Europe_metric_system_MID. So if you select that one in both the project and editor, you will work in liters instead of m3.

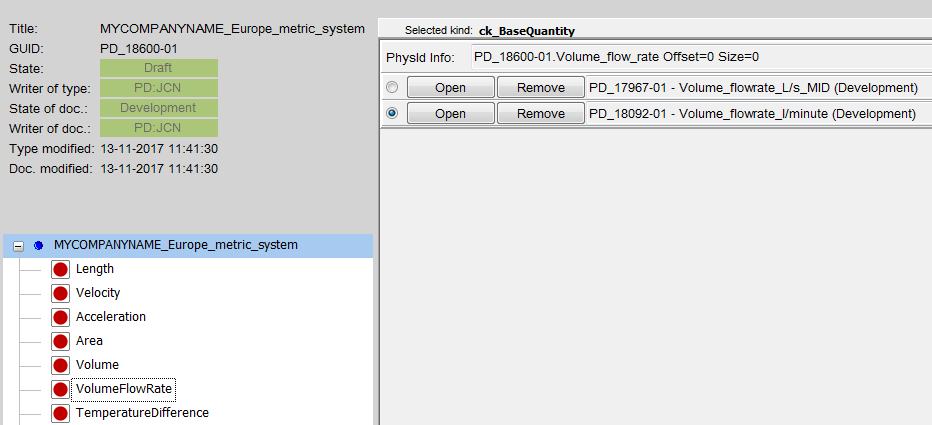

Creating your own derived quantity

If you want eg liters per minute, you first need to create your own local unit.

Open PD_13598 Volume_flowrate_l/s. Rightclick and select “create new type” now rename this new type to “Volume_flowrate_l/minute” and adjust the symbol to “l/m” and the scale to 60000 (1000 to go from M3/s to l/s and another 60 to go from l/s to l/m)

You then need to create your own “quantity local units relation table”.

Open PD_12849 Europe_metric_system_MID. Right-click and press “create new type”. Rename to eg” MYCOMPANYNAME_europe_metric_system”

Then you right-click on “VolumeFlowRate” and select “Add local unit type” and choose the “volume_flowrate_l/minute” you just created. And then you press on the radio button next to your own unit.

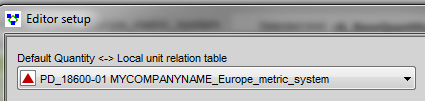

The final step is then to select this new “quantity local units relation table” in your project(right-click on the project name and select “quantity local units relation table”).

You should also add it in your editor (set on the setup screen).

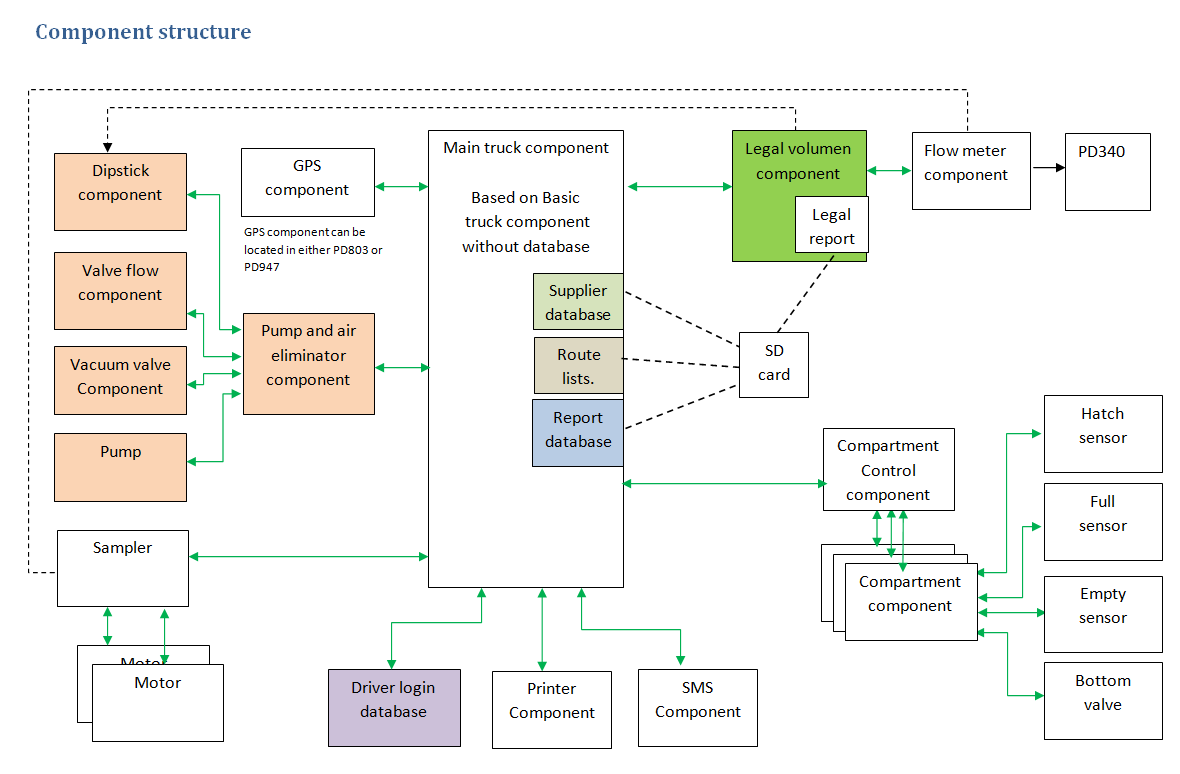

Overall design

In general, PD recommends creating components for “logical functions”. As an example, please see the below component structure for a milk tanker system. By following this method, you can use a broad range of physical components such as pumps and valves. You can even use a combination of them, without having to change any program code. We have made a demo-project PD_17604-02 that implements the described component structure.

Using methods to reduce the number of program lines

Sometimes you find that a method becomes so large that you find it difficult to read. In that case, you have the option to create methods within the component, that you can call from your “too large” method. An example is a functionality used in many places. Another example is to make a method for each state in a state machine. In the end, remember that you can make a supervisor/servant-connection from one component to another. As a result, you can get access to the methods and data in another component.

When you work together on a project in the early stage, it is faster and simpler to use the shared draft state. Use it for both the project as well as the types you use in the project.

You need to share all the types with the people working on the project. They can see and use them, but there is still only one owner. You create a project. Different people can work on different types that you use in the project. As a rule of thumb, split the project into as small pieces as you can. In that way, you don’t have to wait too long for other participants to implement changes.

If you find an error or want to add functionality to one of the types, the type owner can make the changes. Afterward, the type owner should push the types to the shared draft again. You can then go to the specific type and restore type and documentation, and thereby you implement the changes in the project.

You don’t need to create new versions of all the connectors and views for the type. It is primarily of that reason that it is faster and simpler.

There is no notification system in the editor that gives you an update when there are changes to one of the types in the project. As a result, you need to be in a close dialog with your colleagues.

Everyone who contributes to the projects needs to have the same editor version.

In VIGO6, you do not need to know the specific final design of your outputs or inputs for that matter. You can develop all your control code without deciding which type of digital output to use.

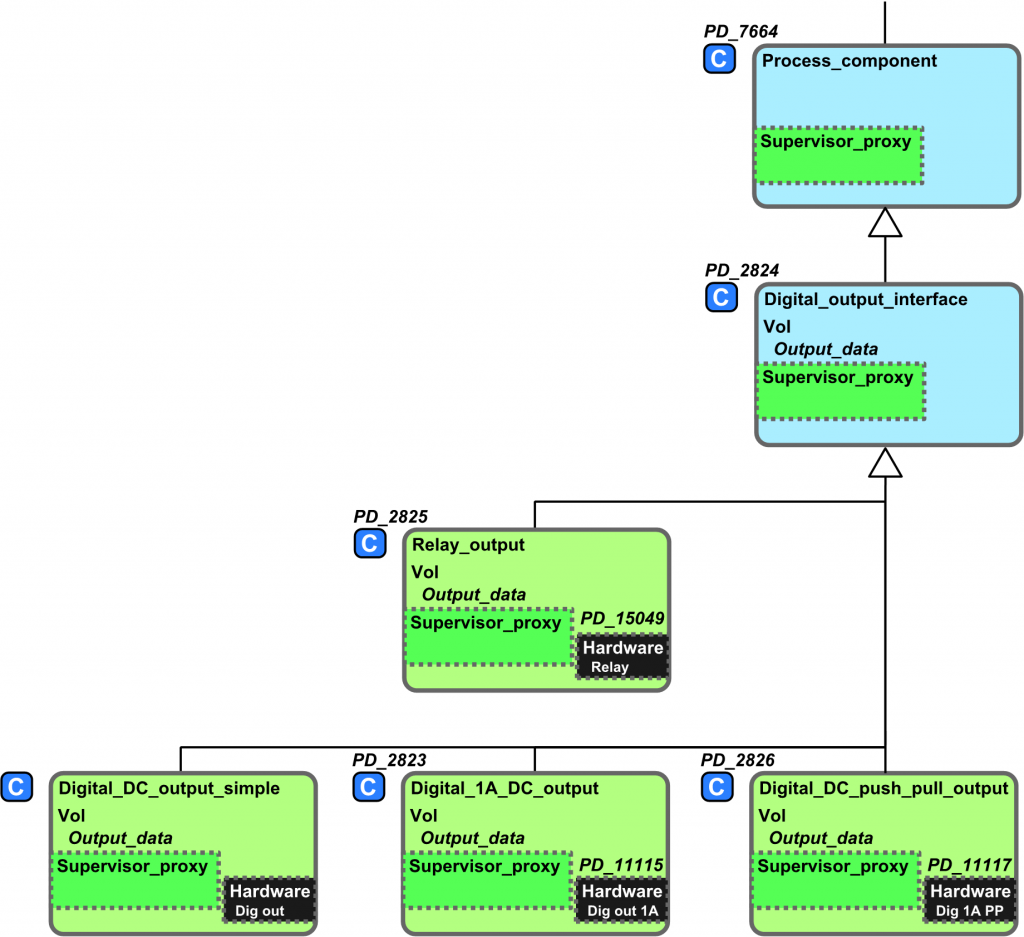

In your control component, you add a connector or servant proxy to ” PD_2824-xx – Digital_output_base”. Now your control code can interface to any of the descendants of the digital output_base. This is illustrated in green color in the inheritance diagram below.

Now you can write your control code that controls the (generic) output.

You can also see tutorial 1:

Once you have made the decision about the type of output, you can proceed. Let us assume that you have selected a relay output.

In your assembly you simply:

- Add the relay output component(PD-2825) and your control component.

- Connect the two

- Locate the relay and control component in PD850 (or in another suitable device)

You can also see tutorial 2:

The programming language in VIGO6, called COPP, is similar to PROCESS-PASCAL, so this part should be no problem.

And the VIGO6 platform contains many improvements that will make development easier, including:

- In VIGO6 you build and test functionality one time, and then you can use it again. No copy-paste – you just add the component to your assembly.

- In VIGO6 you have a lot of premade components that you can use in your project. It can be a pump valve or flow meter components.

- In VIGO6, you tie the visualization to a component or assembly, and you can reuse it.

- In VIGO6, you have better options for the maintenance of existing systems. There are no settings done directly on the modules – as was the case in VIGO5. As a result, when you locate your project for the system, you know what is running, can make the updates you want, and then build and download the new program.

- In VIGO6 you can replace a faulty module on-the-fly. You simply remove the faulty module and plug in a new one, type in the Serial Number of the new module and you are back in business.

See also advantages in VIGO6.

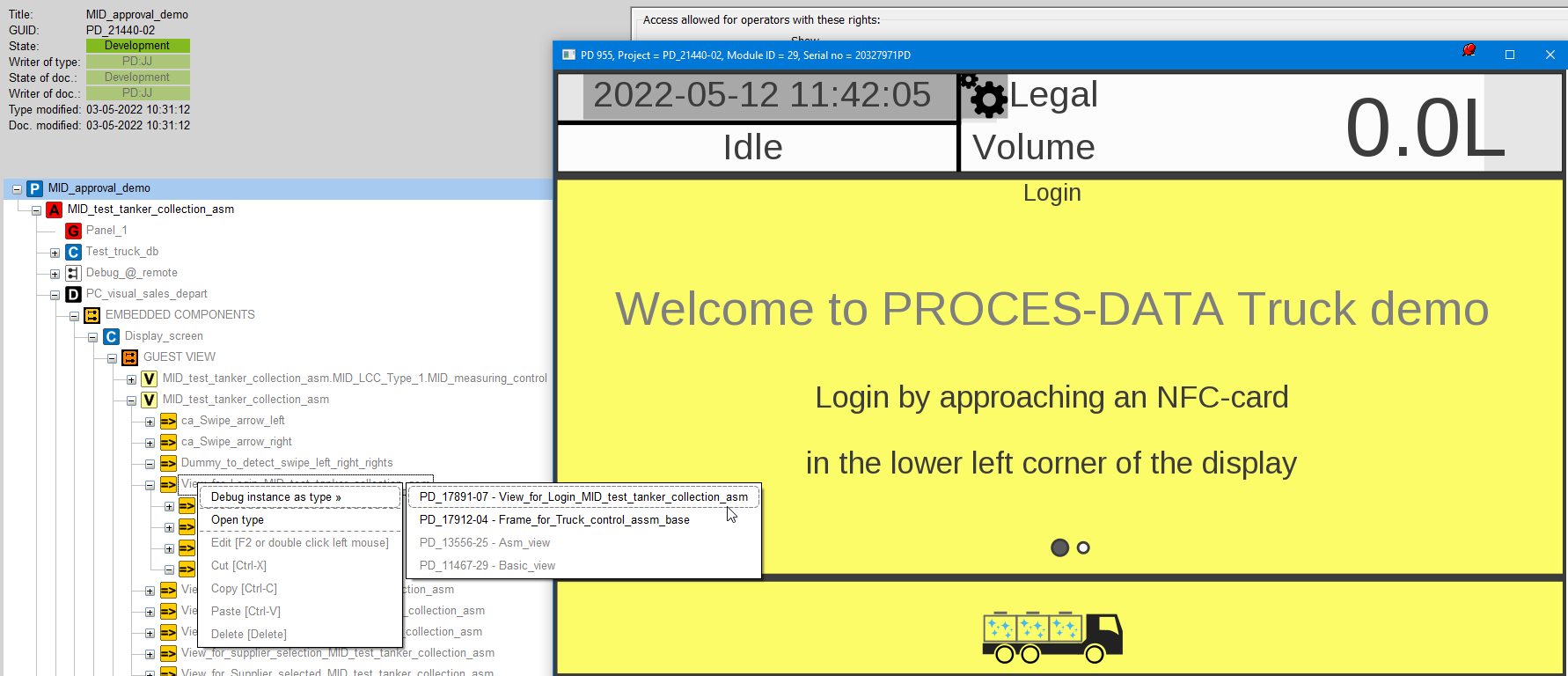

It is possible to debug any visualization. The only requirements is that the visualization you want to debug, must be running (meaning; the visualizations-COPP-program is executing.

Find the view you want to debug at the device where you have added the visualization, (or the visualization containing the visualization you want to debug (here you need to find the specific view you want to debug by clicking the + until you find it)), and then debug it, as you would do with a control component.

The VIGO6 editor is bound to be in one directory on one PC. Here your personal key is. This personal key is used when creating new GUID’s aso. Therefore, this key is yours personally and must only exist once. Copying it may cause creating more than one component with the same GUID, and this will cause you problems we cannot help you with. So this is a NO-GO!!.

Next, whatever GUIDs may be created on one PC, is not automatically copied to the other PC. Here you must either set the GUID’s in Development, or push them in Shared-Draft, and then fetch them on the other VIGO6 on the other PC.

Though, It is possible to ‘move’ the whole VIGO6 directory, but this is a manual process, where you are to move all files and directories to the other PC. In practice, it is time-consuming due to the many files and directories.

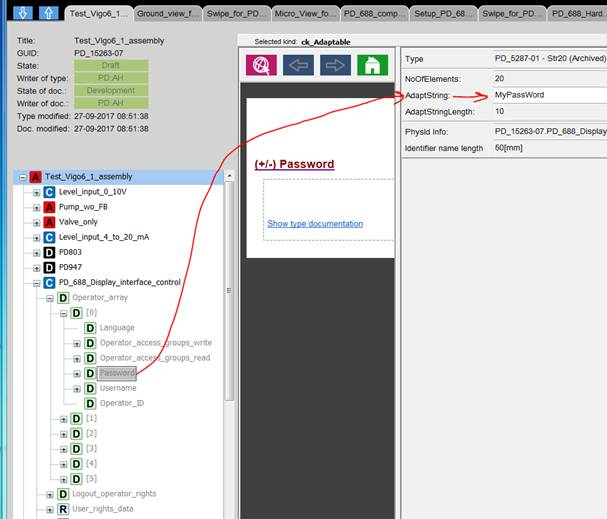

While we suggest using the NFC-reader in the PD688 display unit for easy login, you can also predefine users.

We have created a control component (PD_17553) and visualization (PD_18202) that allow you to create six default users for every display unit in a project. These are instance constants in the control component, so once you have added the component to your project you simply define the default users you want. And of course, remember to locate the component into the display unit.

The user logs in with username + password OR with userID + password.

The password and username are a (text)string. The string value is entered as plain text in the “AdaptString” cell.

See the example for Operator [0].

NoOfElements is the string length, 0,1,2,3 … is the elements of the string. So since NoOfElements is 20, the password can be up to 20 characters long.

Tip:

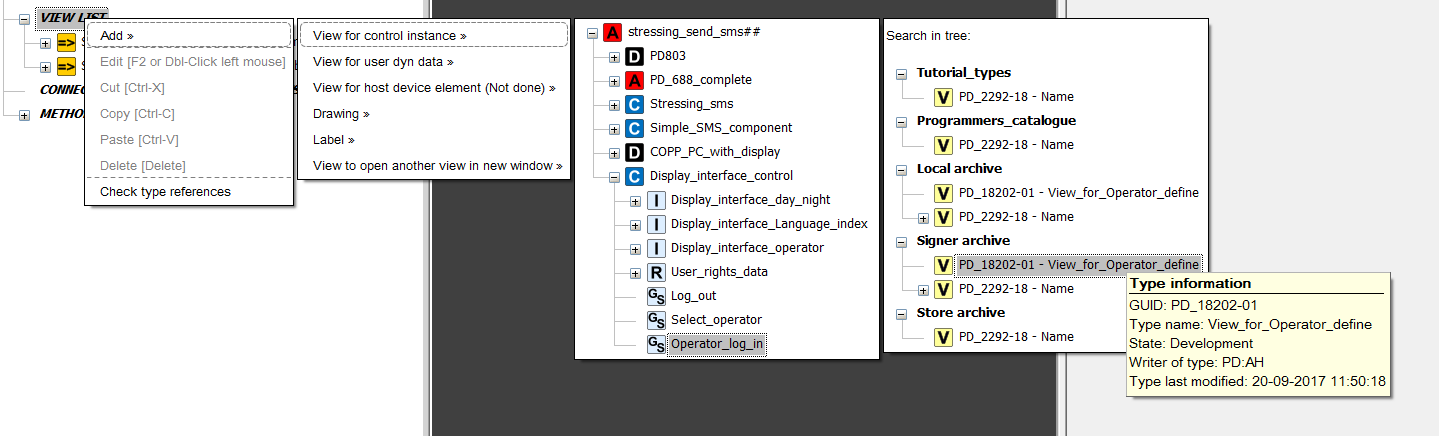

To add the visualization, you need to find the get/set method of the “Operator_log_in” (see the attached screen dump)

It is always possible to load whatever version there is ‘pushed’ to the signer. In case the version you want to ‘restore’ is in Shared_Draft, you can just restore is, but please be aware; your possible local changes since the GUID were last sent to the signer will be lost.

The best way to work, is to set a version in Development (which ‘push’ this version to the server), and it is now locked. Then create a new version for further development of the GUID. In this way one can always restore a specific version. In case you have written in the documentation what functions are in what version, it will ease the usage even more.

Visualizations

Yes, you can. Please see this tutorial, where you will get detailed instructions on how to create your own keyboard.

It is possible to clone a visualization, and thereby have an exact copy, with all the same views on the VIEW LIST.

Afterwards you can change this clone to show what you want (add visualization or delete visualizations).

Have a look at tutorial 6:

It explains hohttps://www.vigo6.com/tutorial-6-adding-views-main-view/w to add either standard buttons or custom made buttons

NB! The view always opens in its built-in size. It means, there is no “show on full screen”-mode. But as long as you design your view for your maximum screen size you will get the effect you want.

A swipe <a class="glossaryLink " style="box-sizing: border-box; background: transparent; color: #000000 !important; text-decoration: none; border-bottom: 1px dotted #000000 !important; box-shadow: none; font-family: Arial; font-size: 16px; font-style: normal; font-variant-ligatures: normal; font-variant-caps: normal; font-weight: 400; letter-spacing: normal; orphans: 2; text-align: start; text-indent: 0px; text-transform: none; white-space: normal; widows: 2; word-spacing: 0px; -webkit-text-stroke-width: 0px;" href="https://www.vigo6.com/glossary/view/" data-cmtooltip="

For example, you can create views for:

- Simple data types – for example, number, enumerated, and booleans that show the values on the screen.

- Control components: They often show data views that represent the registers in the control component.

- Assemblies: They often show a combination of component views and other assembly views.

- Projects: Views for projects combine the views of all the instances that you add to the project.

“>view consists of several frames. Check this tutorial to see how to create it!

Check this tutorial upon language and operator access rights!

Whenever the GURU-bug is shown on say the PD688, please take a photo of it, and note the PD688 device-version (PD_xxxx-xx), and also what Customware is loaded into it (the project GUID and which device in the project it is), and return this information to us. Depending on our findings, we may then request a support-file of the project in case it has root in the customware, or in order to be able to recreate the error at PROCES-DATA to find the cause. Naturally the content of the support-file is your private property, and we will never publish or use any part of it, without asking you first. It could be as an example in education-material or other purposes.

It is not directly possible to have a fast flashing text.

One way is to visualize a Boolean in a control-component like described here: https://www.vigo6.com/how-to-display-a-blinking-message-for-a-variable/

Another way is to have a qBool in the Dynamic Variables section of your view, and then toggle this every time then Paint() Method in executed. This Boolean then determine whether to show the text or not. The blink-frequency is though out of your control, and will depend on how often the view is redrawn (how often visualized data changes)

Paint() method override example:

IF My_qBool THEN My_qBool:= FALSE ELSE My_qBool:= TRUE FOR Viewlist_index:= 0 TO NoOfChildren-1 DO IF Viewlist_index = Label_to_flash THEN IF My_qBool THEN Call_viewlist_paint(ViewListIndex:= Viewlist_index) ELSE Call_viewlist_paint(ViewListIndex:= Viewlist_index)

(For example, in a system with 2 identical systems to be controlled individually. (left part of the screen for one system and right part of the screen for the second system)

One cannot have more than on selector-view in a the same view, but you can have 2 views on your screen (add two identical views to the Guest-list of a device with a Display, one for each system), and each view can contain one selector-view. It is also possible that you open the two selector-views from two buttons, and each selector-view then will exists in each view (window).

Yes, this is “as designed”.

But of course, you have several options to change the default behavior of the screens. Just refer to this tutorial!